Quia consequat fermentum reiciendis vel vestibulum doloremque odit earum ex? Aenean fuga cubilia, beatae! Suspendisse malesuada ab, impedit! Ullam volup tatem, malesuada, aenean proident.

Our comprehensive range of steam traps provides energy efficiency, minimal steam loss, corrosion resistance, air and CO2 venting, operation against back pressure, freedom from dirt problems, and long, reliable service for your application and industry.

| Inverted Bucket Steam Traps | Float and Thermostatic Steam Traps | Controlled Disc (Thermodynamic) Steam Traps | Thermostatic Steam Traps – Bellows, Wafer, Bimetallic

Faster, more accurate, and much safer than traditional methods, Armstrong’s Steam QM® Series automatic steam quality monitoring provides reliable, state-of-the-art solutions for determining and communicating the dryness fraction of steam, amount of superheat present, concentration of noncondensable gases in steam, and more.

Armstrong offers tailor-made and completely pre-assembled packages that include steam distribution and condensate collection manifolds, Trap Valve Stations (TVS), steam traps, thermostatic start-up and freeze protection valves. Our steam tracing equipment gives you significant advantages, such as shorter installation time, easier maintenance, improved safety and higher energy savings.

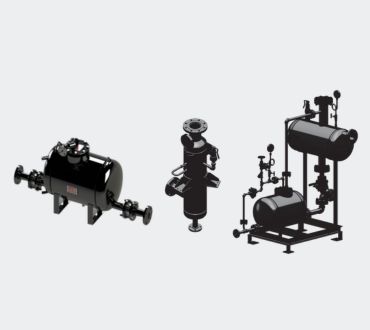

Armstrong offers a complete line of pumps to handle all your condensate recovery needs, including:

| Pump Trap Packages | Double Duty® Steam Trap/Pump Combination | Electric Pump Packages | Boiler Feed Systems | Flash Recovery Vessels

Armstrong offers pressure and temperature controls and regulating valves to help you manage steam, air and liquid systems safely and efficiently, and ensure uninterrupted productivity.

| Pressure Reducing Valves (PRVs) – Direct Acting, Piloted

| Control Valves – Pneumatic, Electric

Armstrong’s Y-type, T-type and Fabricated Basket Pipe Strainers are available in a wide choice of sizes and materials to meet your pipeline straining requirements.

Armstrong’s Float-Operated Drain Traps are designed for draining heavy liquids from gases or light liquids (dual gravity drainers). These liquid drainers can operate to 1800 psig / 255 barg or specific gravity down to 0.40.

Armstrong’s Float-Operated Air Vent Relief Traps are designed to remove gases from liquids down to 0.40 specific gravity, and thermostatic devices are available to evacuate gases from steam systems.

Accurate flow measurement is vitally important in many institutional and industrial environments, and for some operations, it can have a significant impact on the bottom line. Armstrong’s VERIS flow measurement technology for steam, liquid and gas delivers exceptional accuracy and reliability in any application.

Armstrong is a global leader in best-in-class hot water products and systems for institutional hygiene and industrial process applications. Our solutions can provide infection control, scald protection, scale removal and inhibition, sustainability, and compliance, while delivering dependable hot water at precision temperatures. We work closely with those tasked with hot water system design, operation and maintenance to optimize performance and user safety.

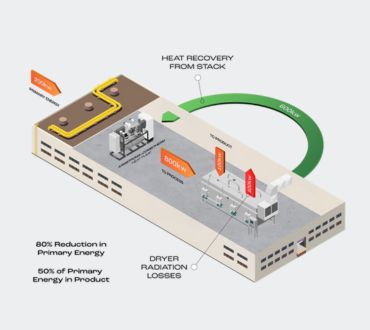

By reclaiming your wasted heat and converting it for use in your industrial process, Circular ThermalSM significantly improves the thermal efficiency of your facilities and reduces your need for fossil fuels. Depending on your industry, overall energy consumption for your plant could decrease by nearly 50% — without reducing available energy for your processes or level of production.

As your thermal utility partner, Armstrong can keep your thermal utility system running smoothly, efficiently and safely, day after day. Whether it’s short-term supervision, ongoing management of your entire thermal utility infrastructure, or training to help you manage your system more efficiently, we have the expertise to complete your project on time and on budget.

Proactive steam trap management is one of the most important steps you can take towards reaching your net-zero goal. Our best-in-class methodology is engineered to maintain low trap failure rates, which can lower energy use and environmental emissions, reduce production stoppages, and increase efficiency and safety.

Thermodyne Engineers specializes in innovative engineering solutions, offering high-quality products and services for industrial and mechanical applications. Committed to excellence, they deliver reliable and efficient solutions tailored to customer need.

WhatsApp us